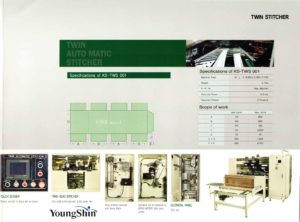

Young Shin Twin Stitcher

The Young Shin Twin Stitcher – KS-TWS attaches two pieces of corrugated together utilizing the newest technology and stitching. The Twin Stitcher can stitch both up and down simultaneously reducing the time and manpower necessary to complete the job. The unit is easy to operate minimizing training time while the Twin Stitcher’s touch screen advises the operator of the status and condition of the machine. The unit can handle a significant amount of material at one time maximizing production while the Servo Motor provides precision and speed throughout the stitching process.

| Model | KS-TWS |

| Machine Area | W·L·H (3000 × 5000 × 1700 mm) |

| Weight | 5 Tons |

| R·P·M | Max 380/min |

| Required Power | 13.5 Kw |

|

TOUCH SCREENEnables the operator to set-up the job via the screen. |

|

TWIN HEAD STITCHERThe unit can stitch both up and down simultaneously. |

|

CONSTANT DISTANCEThe distance required for the job stitching is constant due to the operation of the Servo Motor. |

|

PRECISE ACCURACYThe operation of the Twin Stitcher is precisely controlled by the Servo Motor’s double axes control. |

|

ELECTRICAL PANEL AND PLC UNITThe operation of the Twin Stitcher is precisely controlled by the Servo Motor that is driven by the PLC unit in the electrical panel. |